Schroefcompressoren

Olie-geïnjecteerde schroefcompressor

SI-serie

Dankzij een innovatieve schroefcompressortrap en een zeer efficiënte permanente magneetmotor van klasse IE5 bereiken de eentraps olie-geïnjecteerde persluchtaggregaten van de SI-serie een zeer hoge energie-efficiëntie - zelfs bij gedeeltelijke belasting. Dit maakt aanzienlijke energiebesparingen mogelijk bij het opwekken van perslucht en draagt aanzienlijk bij aan zuinige, grondstofbesparende en duurzame processen.

Volumestroom:

17

tot

726

m3/h

Drukverschil (Δp):

5.500

tot

13.000

mbar

Medium:

Lucht,

Neutrale gassen

Compressie:

olie-geïnjecteerd

De voordelen van de AERZEN biogascompressor van de SI-serie in één oogopslag:

- Maximale energie-efficiëntie - zelfs bij gedeeltelijke belasting

- Lagere investeringskosten dankzij de uitgebreide subsidiabiliteit op basis van de BAFA-subsidieprogramma's

- Uitgebreid volumestroomregelbereik door geïntegreerde VFD-technologie

- Ongeëvenaarde betrouwbaarheid dankzij een innovatief aggregaatontwerp

- Veilig gebruik in extreme omgevingsomstandigheden en met de moeilijkste vereisten

- Maximale ruisonderdrukking dankzij innovatief aggegaatontwerp

- Lagere onderhoudskosten door langere onderhoudsintervallen en doordat rollagers in PM-motoren niet langer nodig zijn

- Compact ontwerp leidt tot een zeer kleine voetafdruk

Zo divers als uw toepassingen

Perslucht is alomtegenwoordig in de industrie en is onmisbaar geworden in vele toepassingen - of het nu gaat om chemische/ petrochemische procestechnologie, elektronica en halfgeleiderproductie en vele andere gebieden.

Elektrische en halfgeleiderindustrie

Het volgende is van toepassing op de procesvereisten: De perslucht moet schoon en droog zijn; stilstand door vervuilde systemen of hele productpartijen moet koste wat het kost vermeden worden. Hoge betrouwbaarheid en beschikbaarheid zijn een must.

Chemische en petrochemische industrie

Een ononderbroken continue werking in chemische fabrieken vereist een continue toevoer van perslucht. Onze krachtige compressoren garanderen een betrouwbare werking. De levensduur van de aggregaten is een belangrijk aspect wanneer de installaties continu worden gebruikt.

Olie- en gasindustrieën

Warmte, elektriciteit en benzine zijn de producten in deze branche. Perslucht speelt een centrale rol in de productie. Pneumatische toepassingen in de olie- en gasindustrie zijn uitdagend en vereisen het hoogste veiligheidsniveau. Het regelsysteem, het instrument of de bufferlucht moeten 100% olievrij werken.

US Units

No- Type bouw

- Schroefcompressoren

- Design

- Overdruk

- Drukverschil (Δp)

- 5.500 tot 13.000 mbar

- Volumestroom

- 17 tot 726 m3/h

- Medium

- Lucht, Neutrale gassen

- Compressie

- olie-geïnjecteerd

Uitstekende energie-efficiëntie

- Aanzienlijke energiebesparingen door extreem hoog rendement in de compressortrappen, in combinatie met de zeer efficiënte PM-motor, met een energie-efficiëntie van ongeveer 96% - zelfs bij gedeeltelijke belasting (klasse IE5-IE6).

- Innovatieve en robuuste schroefcompressortrappen met nieuwe, zeer efficiënte 4+6 profielen

- Verhoogde turndown door gericht gebruik van VFD-technologie

- Geoptimaliseerde koeling van de compressortrap en motor dankzij dubbelwandige koelmantels in beide units. Koeling en smering worden gerealiseerd door een gemeenschappelijk oliecircuit voor zowel de compressor als de motor

- De PM-motor heeft een hoog rendement, zelfs bij lage snelheden. De gevraagde hoeveelheid perslucht wordt naar behoefte aangepast door middel van een VFD. De geharmoniseerde combinatie van de hoogwaardige aandrijflijn en de zeer efficiënte compressortrap resulteert in een bijzonder efficiënte werking van het hele systeem.

- De rotor van de PM-motor is rechtstreeks verbonden met de compressor-as, zodat extra verliezen in de aandrijflijn worden vermeden

Hoge betrouwbaarheid en duurzaamheid

- Het compacte ontwerp van de compressortrap en aandrijflijn, die toch optimaal toegankelijk zijn, vereenvoudigt het onderhoud van deze eenheid. De PM-motor heeft helemaal geen antifrictielagers nodig en wordt daarom gekenmerkt door een bijzonder hoge onderhoudsvriendelijkheid

- Uitgebreide toepassingsgebieden: optie voor veilig gebruik bij bijzonder hoge of lage omgevingstemperaturen, tot gebruik in extreme externe omstandigheden, zoals installatie in poolgebieden of in woestijngebieden

- Verhoogde levensduur van de lagers tot 30.000 uur voor compressortrappen

- De permanente bewaking van de druk en de bedrijfstemperaturen maakt een zeer betrouwbare werking van het hele systeem mogelijk

- De oliekoeler die standaard wordt meegeleverd, verhoogt de betrouwbaarheid van het aggregaat op duurzame wijze in extreme klimaatomstandigheden

Minder onderhoud

- Bediening en onderhoud uitsluitend vanaf de bedienings- en achterkant

- Dankzij PM-motortechnologie zijn de smering van de antifrictielagers en een lagerwissel overbodig

- Eenvoudig transport van het volledige, compacte aggregaat, naar keuze met palletwagen, vorkheftruck of kraan. Bij levering is de machine al gevuld met olie; de machine hoeft dus niet te worden gevuld met olie als onderdeel van het inbedrijfstellingsproces

Intelligent oliesysteem

- Er is slechts één oliecircuit nodig voor smering en koeling van de compressor en motor.

- De geïntegreerde oliedruksmering van de lagers maakt lagers met een levensduur tot 30.000 uur mogelijk

Intelligent gereduceerd geluidsniveau

- Minimale geluidsdrukniveaus van 70 dB(A) worden bereikt

- Afhankelijk van uw eisen, kunt u kiezen uit verschillende opties voor geluidsisolatiematerialen, geluiddempertechnologieën en akoestische kapontwerpen

- Hoogwaardige aanzuigregelaar voor de vermindering van aanzuigverliezen en geluid

- Geluidstechnisch geoptimaliseerde akoestische kap

- Dankzij de oliekoelmantel voor de PM-motor en het gebruik van een centrifugaalventilator worden de laagste geluidsniveaus gerealiseerd

Olie-geïnjecteerde schroefcompressor

SI-serie

—

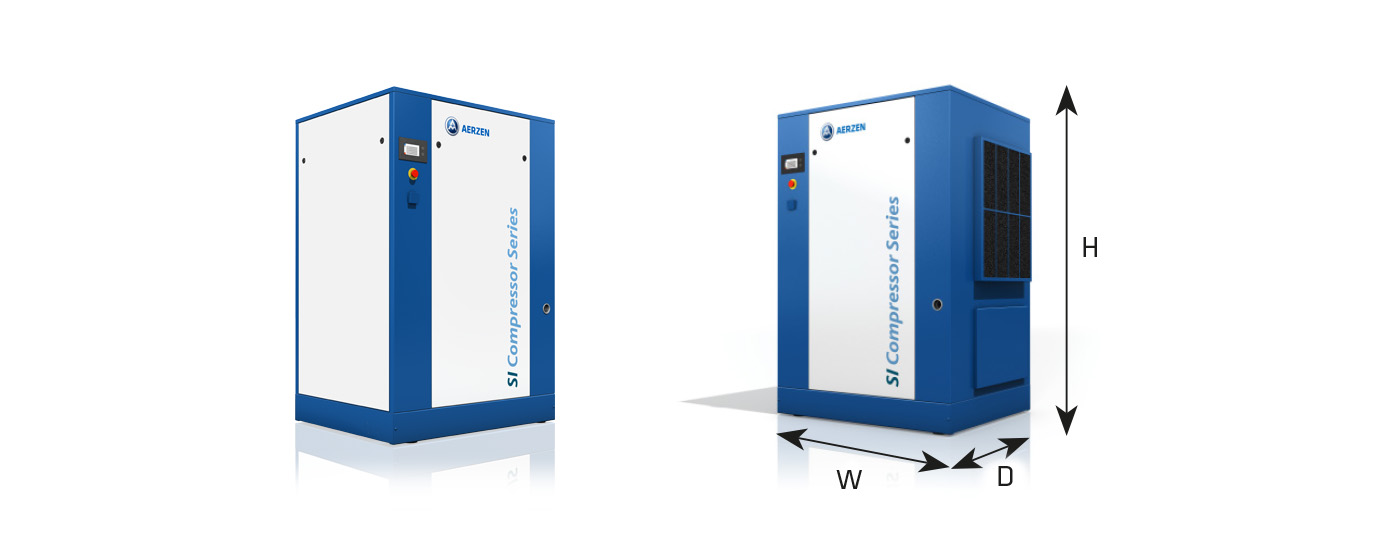

Prestaties & afmetingen

| Serie | Gegevens over prestaties | Afmentingen en gewichten | |||||

|---|---|---|---|---|---|---|---|

| Drukverschil, mbar | Volumestroom*, m3/h | Motorvermogen, kw | Breedte (W), mm | Diepte (D), mm | Hoogte (H), mm | Gewicht, kg | |

| SI 8 A/W** | 8 bar | 8,000 | 63 | 8 | 660 | 875 | 1,250 | 215 |

| SI 8 A/W** | 10 bar | 10,000 | 52 | 8 | 660 | 875 | 1,250 | 215 |

| SI 8 A/W** | 13 bar | 13,000 | 42 | 8 | 660 | 875 | 1,250 | 215 |

| SI 11 A/W** | 8 bar | 8,000 | 89 | 11 | 660 | 875 | 1,250 | 220 |

| SI 11 A/W** | 10 bar | 10,000 | 76 | 11 | 660 | 875 | 1,250 | 220 |

| SI 11 A/W** | 13 bar | 13,000 | 67 | 11 | 660 | 875 | 1,250 | 220 |

| SI 15 A/W** | 8 bar | 8,000 | 142 | 15 | 660 | 875 | 1,250 | 250 |

| SI 15 A/W** | 10 bar | 10,000 | 116 | 15 | 660 | 875 | 1,250 | 250 |

| SI 15 A/W** | 13 bar | 13,000 | 98 | 15 | 660 | 875 | 1,250 | 250 |

| SI 19 A/W** | 8 bar | 8,000 | 175 | 19 | 770 | 850 | 1,450 | 300 |

| SI 19 A/W** | 10 bar | 10,000 | 150 | 19 | 770 | 850 | 1,450 | 300 |

| SI 19 A/W** | 13 bar | 13,000 | 117 | 19 | 770 | 850 | 1,450 | 300 |

| SI 22 A/W** | 8 bar | 8,000 | 216 | 22 | 770 | 870 | 1,450 | 320 |

| SI 22 A/W** | 10 bar | 10,000 | 183 | 22 | 770 | 870 | 1,450 | 320 |

| SI 22 A/W** | 13 bar | 13,000 | 157 | 22 | 770 | 870 | 1,450 | 320 |

| SI 30 A/W** | 8 bar | 8,000 | 281 | 30 | 850 | 980 | 1,750 | 470 |

| SI 30 A/W** | 10 bar | 10,000 | 252 | 30 | 850 | 980 | 1,750 | 470 |

| SI 30 A/W** | 13 bar | 13,000 | 220 | 30 | 850 | 980 | 1,750 | 470 |

| SI 37 A/W** | 8 bar | 8,000 | 370 | 37 | 850 | 980 | 1,750 | 540 |

| SI 37 A/W** | 10 bar | 10,000 | 320 | 37 | 850 | 980 | 1,750 | 540 |

| SI 37 A/W** | 13 bar | 13,000 | 275 | 37 | 850 | 980 | 1,750 | 540 |

| SI 45 A/W** | 8 bar | 8,000 | 443 | 45 | 950 | 1,180 | 1,750 | 660 |

| SI 45 A/W** | 10 bar | 10,000 | 386 | 45 | 950 | 1,180 | 1,750 | 660 |

| SI 45 A/W** | 13 bar | 13,000 | 332 | 45 | 950 | 1,180 | 1,750 | 660 |

| SI 55 A/W** | 8 bar | 8,000 | 562 | 55 | 950 | 1,180 | 1,750 | 790 |

| SI 55 A/W** | 10 bar | 10,000 | 505 | 55 | 950 | 1,180 | 1,750 | 790 |

| SI 55 A/W** | 13 bar | 13,000 | 426 | 55 | 950 | 1,180 | 1,750 | 790 |

| SI 75 A/W** | 8 bar | 8,000 | 726 | 75 | 1,330 | 2,300 | 1,670 | 1,600 |

| SI 75 A/W** | 10 bar | 10,000 | 672 | 75 | 1,330 | 2,300 | 1,670 | 1,600 |

| SI 75 A/W** | 13 bar | 13,000 | 548 | 75 | 1,330 | 2,300 | 1,670 | 1,600 |

Geluidsdrukniveau zonder afblaaslawaai, met akoestische behuizing.

* komt overeen met de gemeten leveringsvolumestroom omgezet naar de klantspecifieke innamecondities p = 1,0 bar , t =20°C, rF = 0%

**Cooling: A: air-cooled and W: water-cooled