Biogas applications present special technology requirements. The AERZEN process gas specialist has therefore developed an application-specific portfolio of standardised solutions for the treatment and feed-in of biogas, which masters the challenges typical of the industry with ease. The innovative screw compressors are characterised by ATEX-compliant engineering and are designed for continuous operation with high final pressures. The high availability and quality ensure maximum process reliability. Extensive modification options offer scope for customisation down to the smallest detail.

Biogas plants convert organic material into biogas containing methane. Not only plant and animal residues are used as raw materials, but also leftovers from the food industry. Microorganisms decompose the biomass in the fermenter into gas containing methane. The resulting raw biogas can be fed into the block-type thermal power station (CHP) after being desulphurised accordingly. Or it is cleaned of CO2 and other impurities in a further processing step and fed into the natural gas grid, for example, as processed biomethane.

Green gas: AERZEN biogas solutions

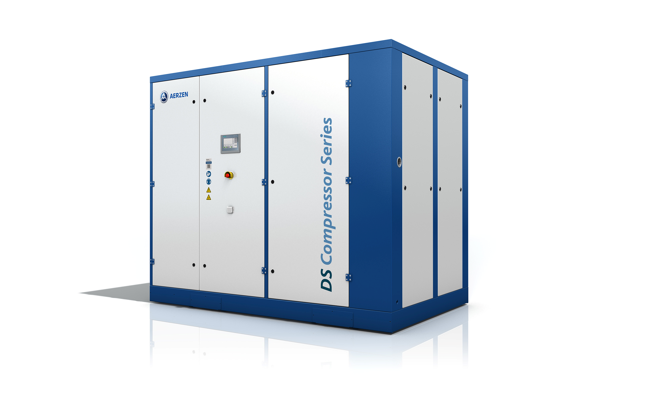

Whether producing biomethane, feeding it into kilometre-long supply networks or pre-pressure generation for block-type thermal power stations: Suitable for the different required suction and final pressures and processes, AERZEN offers a bespoke portfolio of blowers and compressors specially developed for the biogas market . These include the oil-injected screw compressor series VMX and VMY. The packages are characterised by maximum energy efficiency, system availability and service-friendliness as well as a large variety of types and many modification options. They work reliably in operation 24 hours a day. The biogas compressors are based on a concept of clear separation between the internals of the package and the environment and are therefore technically gastight.

Biogas compressor VMX: diversity of performance for a wide range of applications

The biogas compressor of the VMX series is an oil-injected screw compressor in five sizes for volume flows of up to 2,500 m³/h and 15 bar g. The forced-conveying machines have a direct drive and impress across the board in rigid everyday use. They are very robustly built, extremely durable and particularly energy efficient. All stages are designed for VFD operation. The large variety of types, the modular principle and the extensive modification options ensure a wide range of applications.

Biogas compressor VMY: final pressures up to 25 bar g

The oil-injected biogas compressors of the VMY series enable a final pressure of up to 25 bar g and allow a raised intake pressure of up to 8 bar g. They are designed for volume flows of up to 6,300 m³/h and are available in three sizes. The rotors of the VMY compressors work without timing gears. This ensures contact-free rotation and optimum efficiency. The packages are insensitive to fluctuating process parameters and gas compositions and are equipped with a hydraulic actuated slide valve (slide control) for infinitely variable control of the volume flow. Like the compressors in the VMX series, the VMY screw compressors offer a variety of different types and modification options based on the modular principle. You will find AERZEN at ACHEMA 2024 in hall 8, stand D38.