Screw Blowers

Screw Blower

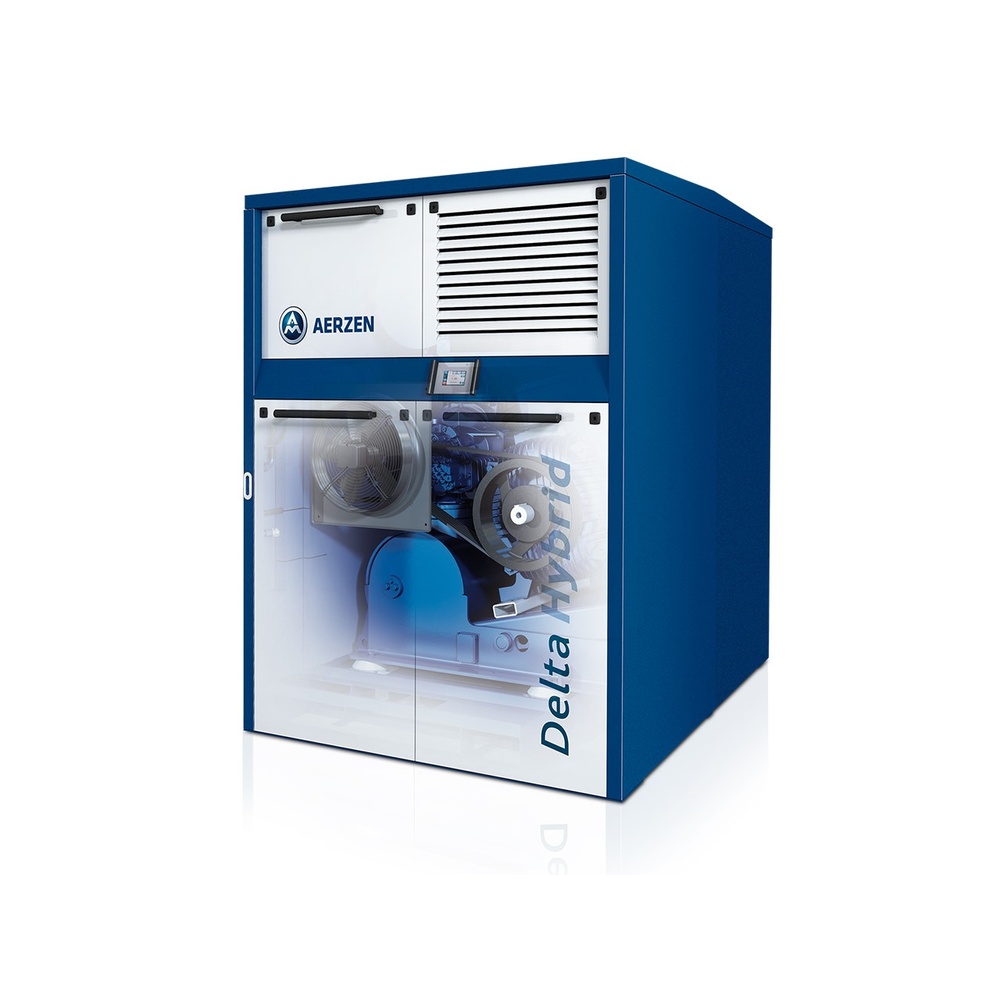

Delta Hybrid belt driven

Delta Hybrid is the perfect synthesis of positive displacement blower and screw compressor. Unlike the conventional positive displacement blower (max. 1,000 mbar), the innovative screw blower uses a new and unique 3+4 compressor profile, which is specially designed for low pressure applications up to 1,500 mbar.

Delta Hybrid thus closes the gap in the previous machine mix and offers a wide range of services for precise design to meet the most diverse process requirements. The result is a new level of cost efficiency for compressed air applications.

Volume flow:

100

to

9.000

m3/h

Differential pressure (Δp):

300

to

1.500

mbar

Medium:

Air

Conveying / Compression:

Oil-free

The advantages of AERZEN Screw Blowers at a glance:

- Highest energy efficiency

- Reduced life cycle costs

- Belt drive: the best mix for efficiency, precise design, flexibility and maintenance

- High reliability and durability also under extreme conditions

- Largest volume flow control range

- Reduced maintenance

Extending the functional range for a wide variety of applications.

The Delta Hybrid is used in a wide range of key industrial applications. These units are designed for the oil-free conveyance of air and neutral gases. For positive and negative pressure use in nominal widths from DN 100 to DN 300.

Delta Hybrid screw blowers can be used globally. Also in zones where extreme ambient temperatures of -40°C to +50°C prevail. With Delta Hybrid, discharge temperatures of up to 230 °C are possible today. The prerequisite for operational reliability in all processes.

AERZEN Engineering

Where a standard solution is not sufficient, AERZEN develops special designs or special machine configurations. Always with an eye on making the process performance as effective as possible for every power requirement. Special designs include ATEX-compliant machines, special motors, acoustic hoods for special noise reduction or for extreme ambient conditions, special oils suitable for food and bevarage and intake filters with a higher filter class.

Applications

- Sewage treatment

- Drinking water purification

- Pneumatic conveyance of bulk materials

- River and lake aeration

- and many more

Industries

- Sewage treatment

- Chemical and process technology

- Glass and paper manufacturing

- Food industry

- Environmental technology

- and many more

US Units

No- Type of technology

- Screw Blowers

- Design

- Positive pressure

- Differential pressure (Δp)

- 300 to 1.500 mbar

- Volume flow

- 100 to 9.000 m3/h

- Medium

- Air

- Conveying / Compression

- Oil-free

The Delta Hybrid screw blowers

The Delta Hybrid Screw Compressor derives from the fusion between the screw compressor technologies and the rotary lobe blowers. This combination results in a machine that combines the technical advantages of the two concepts, offering new possibilities for generating positive pressure.

Roughly 90% of a compressor’s life cycle costs are consumed by energy. While this presents a huge challenge, AERZEN’s Delta Hybrid is providing companies with ideal solutions that enable large energy savings thanks to its compressor’s energy efficiency, even in high-pressure ranges.

Get the Delta Hybrid screw blower and enjoy benefits such as:

- Reduced life-cycle costs

- Extraordinary energy efficiency

- High reliability levels

- Reduced maintenance needs

- Increased range of pressures and applications

- 100% pure process air, free of absorption materials and oil

There is no more comfortable way to generate pressure.

Significative energy savings, easy installation and commissioning, minimum maintenance: these characteristics are also directly reflected into the cost balance. A good reason for AERZEN to keep a special eye on them during the development of the Delta Hybrid Generation. The results convince even the smartest customers.

Extraordinary energy efficiency

- New and unique 3+4 rotor profile

- Energy savings up to 30% compared to lobe blowers

- Extended turndown ratio up to 1:5

- Optimized air flow within the acoustic hood

- Belt drive to match exactly the process requirements

Extremely compact design

- Space-saving side-by-side installation

- Smaller dimensioning of machine rooms

- Easy access for service and maintenance work

- Integrated power suppy panel having the same footprint

Reliability and durability

- Patented bearing, theoretical lifetime of more than 70,000 hours (at 1.000 mbar pressure difference)

- Patented driving- and conveying chamber sealings

- 100% oil-free and PFAS-free per Class 0 (certified per ISO 8573-1)

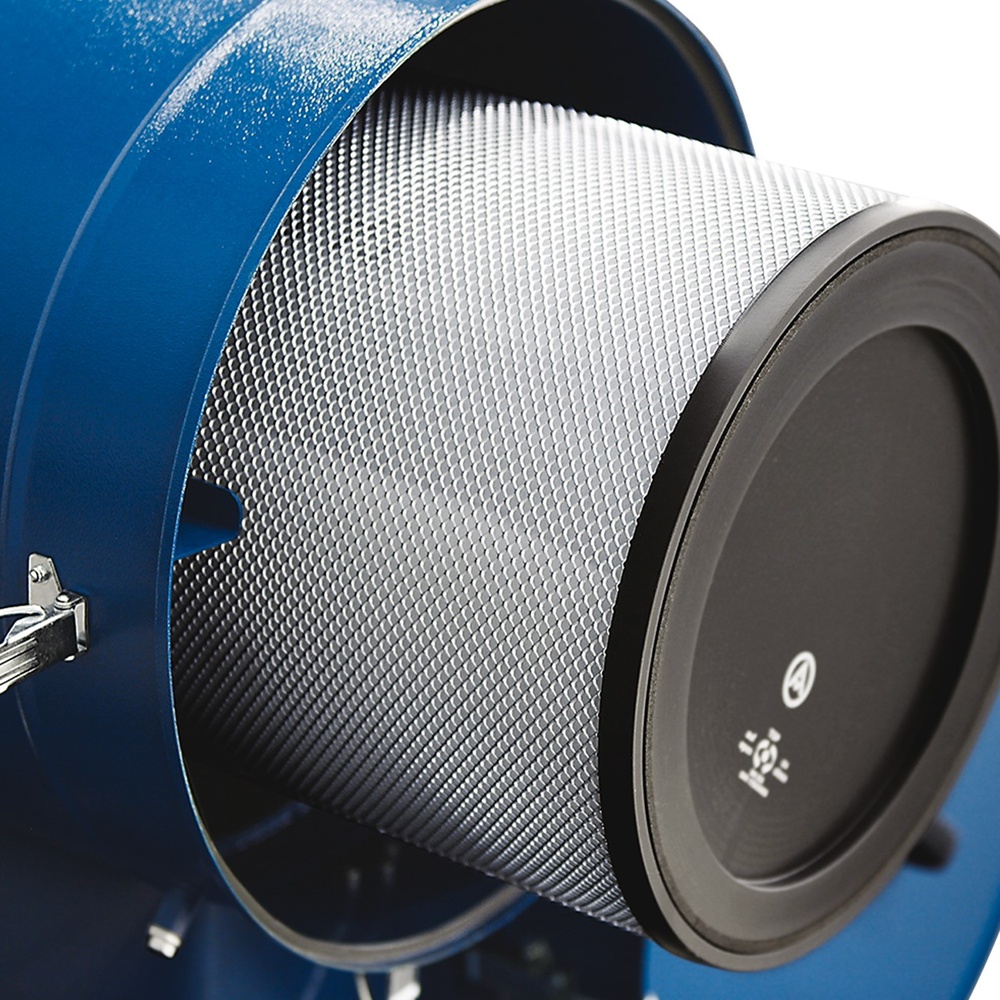

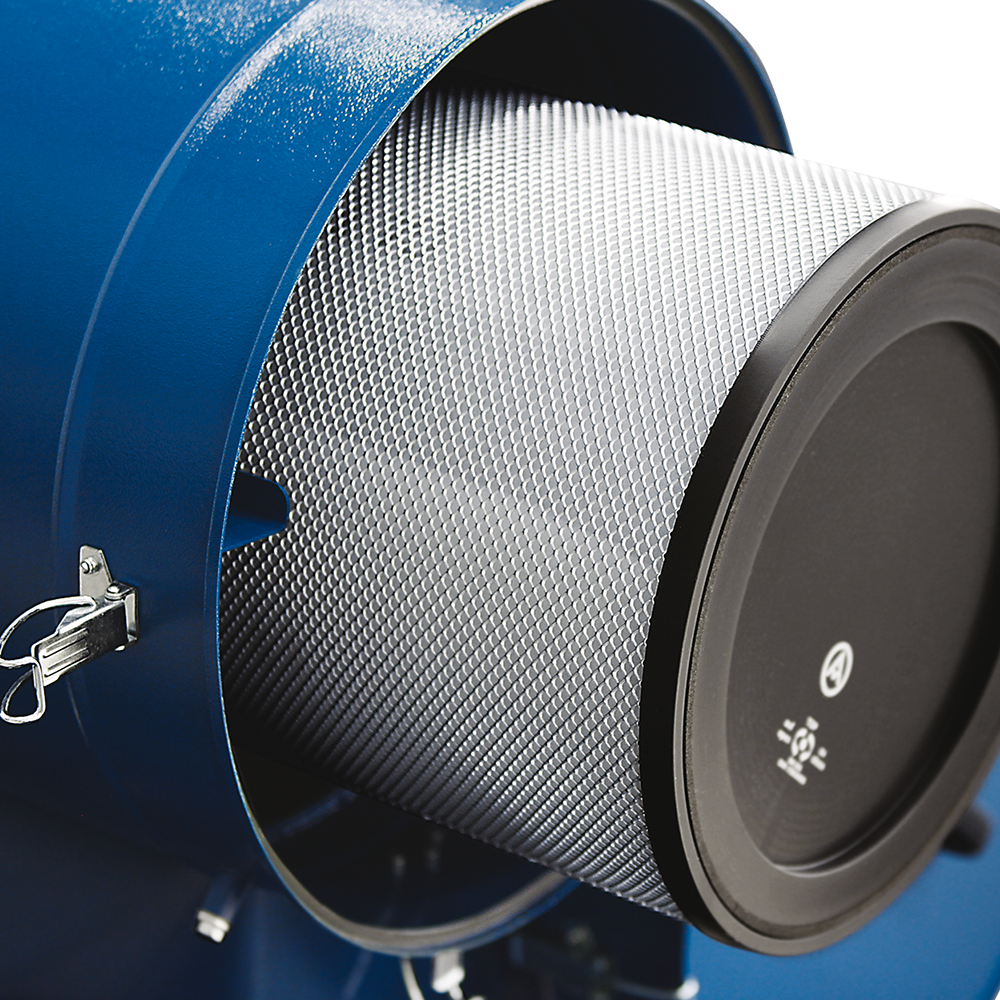

- Patented silencer w/o absorption material

Further information is available within the product brochures.

New Delta Hybrid sizes D13S, D17S, D25S and D30S

Delta Hybrid is among the most innovative solutions in compressor technology - and by far among the most efficient assemblies in its class. Now AERZEN has taken its globally successful screw blowers to the next technology level. The new types impress with smart features, further improved functionality and enormous energy savings of up to 30 % compared to a conventional positive displacement blower.

Screw Blower

Delta Hybrid belt driven

—

Performances & dimensions

| Series | Performance data | Dimensions and weights | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Pressure difference, mbar | Volume flow*, m3/h | Motor power, kw | Sound pressure, max. db(A) | Width (W), mm | Depth (D), mm | Height (H), mm | Nominal size | Weight, kg | |

| D 12 H | 1.500 | 670 | 37 | 73 | 1.250 | 1.350 | 1.500 | DN 100 | 590 |

| D 12 S | 1.000 | 690 | 30 | 72 | 1.250 | 1.350 | 1.500 | DN 100 | 590 |

| D 13 S | 1.000 | 775 | 30 | 72 | 1.250 | 1.350 | 1.500 | DN 100 | 510 |

| D 17 S | 1.000 | 1.010 | 37 | 73 | 1.250 | 1.350 | 1.500 | DN 125 | 520 |

| D 24 H | 1.500 | 1.370 | 75 | 76 | 1.250 | 1.350 | 1.500 | DN 125 | 635 |

| D 24 S | 1.000 | 1.390 | 55 | 74 | 1.250 | 1.350 | 1.500 | DN 125 | 635 |

| D 25 S | 1.000 | 1.440 | 45 | 74 | 1.250 | 1.350 | 1.500 | DN 125 | 630 |

| D 30 S | 1.000 | 1.780 | 55 | 75 | 1.250 | 1.350 | 1.500 | DN150 | 640 |

| D 36 H | 1.500 | 1.900 | 110 | 76 | 1.500 | 1.800 | 1.980 | DN 150 | 1.098 |

| D 36 S | 1.000 | 2.150 | 75 | 76 | 1.500 | 1.800 | 1.980 | DN 150 | 1.098 |

| D 52 S | 1.000 | 3.120 | 110 | 77 | 1.500 | 1.800 | 1.980 | DN 150 | 1.305 |

| D 62 H | 1.500 | 3.400 | 160 | 81 | 1.700 | 2.055 | 2.111 | DN 200 | 1.400 |

| D 62 S | 1.000 | 3.500 | 110 | 79 | 1.700 | 2.055 | 2.111 | DN 200 | 1.400 |

| D 76 H | 1.500 | 4.440 | 160 | 79 | 1.700 | 2.055 | 2.111 | DN 200 | 1.998 |

| D 76 S | 1.000 | 4.550 | 160 | 77 | 1.700 | 2.055 | 2.111 | DN 200 | 1 |

| D 98 H | 1.500 | 5.600 | 250 | 81 | 1.900 | 2.200 | 2.345 | DN 250 | 3.300 |

| D 98 S | 1.000 | 5.800 | 200 | 79 | 1.900 | 2.200 | 2.345 | DN 250 | 3.300 |

| D 152 H | 1.500 | 8.700 | 400 | 81 | 2.100 | 2.850 | 2.345 | DN 300 | 4.050 |

| D 152 S | 1.000 | 8.900 | 315 | 80 | 2.100 | 2.850 | 2.345 | DN 300 | 4.050 |

Sound pressure level without blow-off noise, with acoustic enclosure.

* corresponds to the measured delivery volume flow converted to the customer-specific suction conditions p = 1,0 bar, t =20°C, rF = 0%