Turbo Blowers

Turbo Blower

Aerzen Turbo Generation 5plus

New size Aerzen Turbo AT250-0.9 S G5plus

Aerzen Turbo Blower Generation 5plus is an excellent choice for high-speed turbo blower. This turbo blower is ideal for volume flows between 360 and 9400 m³/h. It has a significantly smaller physical footprint but boasts up to 10% higher operational efficiency than conventional turbo blowers.

Volume flow:

360

to

9.400

m3/h

Differential pressure (Δp):

200

to

1.000

mbar

Medium:

Air

Conveying / Compression:

Oil-free

The advantages of AERZEN Turbo Generation 5plus at a glance:

- 360 to 9400 m³/h air and gas volume flow range

- Speed-controlled

- Plug-and-play design

- Up to 10% more efficient than standard turbo technology

- Extended bearing life due to high-tech AERZEN air bearings featuring double coating for maximum performance and energy efficiency

The right solution for every application

AERZEN successfully introduced its innovative, air bearing turbo blower to the market in 2010. Today, more than 2500 installations worldwide attest to its superior reliability, and low energy and maintenance costs.

Aerzens's turbo blowers are used for a wide range of different applications, including oxygen supply in the biological processes of wastewater treatment plants, fermentation in yeast production, providing oxidation air for lime and cement production, and many more..

US Units

No- Type of technology

- Turbo Blowers

- Design

- Positive pressure

- Differential pressure (Δp)

- 200 to 1.000 mbar

- Volume flow

- 360 to 9.400 m3/h

- Medium

- Air

- Conveying / Compression

- Oil-free

Aerzen Turbo Blower Generation 5plus is another excellent choice for high-speed turbo blower. This turbo blower is ideal for volume flows between 360 and 8400 m³/h. It has a significantly smaller physical footprint but boasts up to 10% higher operational efficiency than conventional turbo blowers.

This space-saving high-speed turbo blower is 100% oil-free. It has numerous applications in water and wastewater treatment, pneumatic transport of bulk materials, and chemical and process technologies.

The key features and benefits of this high-speed turbo blower include:

- 360 to 9400 m³/h air and gas volume flow range

- 100 % ölfrei und PFAS-frei nach Klasse 0

- Speed-controlled

- Plug-and-play design

- Up to 10% more efficient than standard turbo technology

- Extended bearing life due to high-tech AERZEN air bearings featuring double coating for maximum performance and energy efficiency

- Minimal maintenance requirements

There's a lot to be said about the economical Turbo. We'll make it brief here.

AERZEN has built turbo blowers since 1911. Over the years, we’ve continued to perfect these assemblies from a technological standpoint. Along the way, we’ve developed expertise that sets standards worldwide today. It’s reflected in the performance characteristics, in every component, and in all the details of the newest Turbos. Discover the new Turbo Generation 5 and Generation 5plus.

100% Turbo

- For small and large volume flows

- From 300 m³/h to 16,200 m³/h

- Speed-controled

- 100% oil-free and PFAS-free per Class 0

Efficient peak values

- Increase in energy efficiency by up to 10% compared to conventional turbo technology

- Control range of 40% - 100%

- Highly efficient individual components

Innovation driver: the permanent magnet motor

- Extremely high-efficiency and energy-saving permanent magnet motor

- Requires no additional energy to magnetize the rotor

- Outstanding efficiency of an almost constant 96%, even in partial load operation

Innovative AERZEN air foil bearings

- Forward-looking double coating made of Teflon and graphite

- Theoretical bearing lifetime of >80,000 operating hours, regardless of stop and start cycles (>80 starts/stops per hour)

- Resistant to pressure peaks (for example, SBR processes, pulsations caused by positive displacement machines) and compressor surge

- Highly functional without necessary accessories (for example, electric control system, back up bearings, auxiliary electronics such as battery systems)

- Highly reliable operation even during voltage fluctuations and power supply failures

- 100% maintenance free

Further information are available within the product brochure (please select a performance to see the product brochure)

Aerzen Turbo G5plus

The powerful turbo blowers of the Aerzen Turbo series are particularly suitable for use in municipal or industrial wastewater treatment plants and cover with now 21 models a volume flow range from 300 m³/h to 16,200 m³/h and system pressures up to 1,000 mbar.

Turbo Blower

Aerzen Turbo Generation 5plus

—

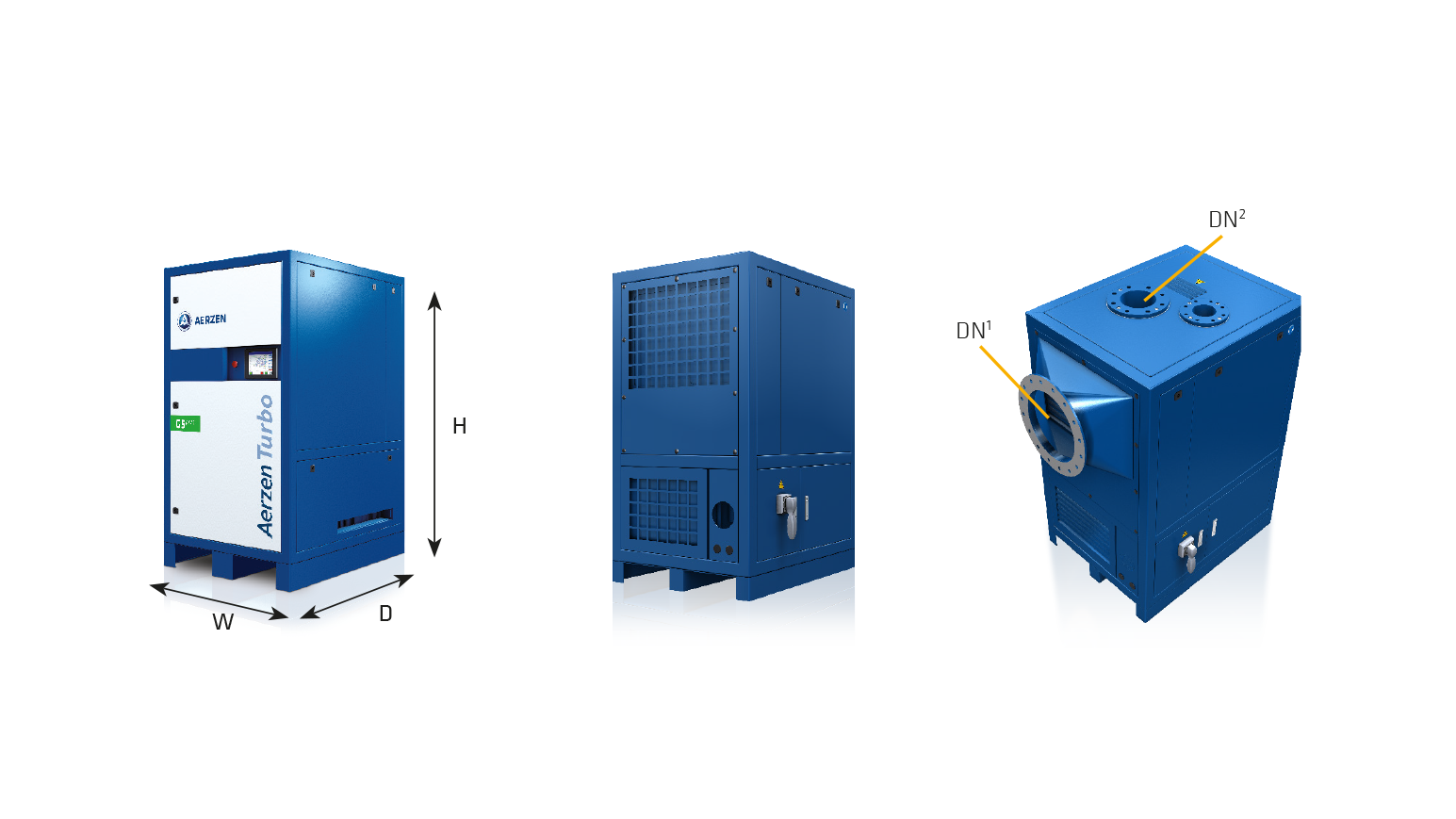

Performances & dimensions

| Series | Performance data | Dimensions and weights | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Pressure difference, mbar | Volume flow*, m3/h | Motor power, kw | Sound pressure, max. db(A) | Width (W), mm | Depth (D), mm | Height (H), mm | Nominal size | Weight, kg | |

| AT 25-0.8 S G5plus | 800 | 900 | 25 | 72 | 800 | 1,040 | 1,500 | DN 100 | 520 |

| AT 35-0.8 S G5plus | 800 | 1,200 | 33 | 72 | 800 | 1,040 | 1,500 | DN 100 | 550 |

| AT 50-0.6 S G5plus | 600 | 2,700 | 40 | 72 | 800 | 1,040 | 1,500 | DN 150 | 750 |

| AT 50-0.8 S G5plus | 800 | 1,900 | 45 | 72 | 800 | 1,040 | 1,500 | DN 150 | 550 |

| AT 60-0.9 S G5plus | 900 | 2,650 | 50 | 73 | 800 | 1,040 | 1,500 | DN 150 | 600 |

| AT 75-0.6 S G5plus | 600 | 3,900 | 65 | 73 | 900 | 1,140 | 1,600 | DN 200 | 750 |

| AT 75-0.8 S G5plus | 800 | 2,900 | 65 | 73 | 900 | 1,140 | 1,600 | DN 200 | 750 |

| AT 100-0.6 S G5plus | 600 | 5,100 | 85 | 73 | 900 | 1,140 | 1,600 | DN 250 | 750 |

| AT 100-0.8 S G5plus | 800 | 3,900 | 85 | 73 | 900 | 1,140 | 1,600 | DN 200 | 750 |

| AT 100-1.0 S G5plus | 1,000 | 3,000 | 85 | 73 | 900 | 1,140 | 1,600 | DN 200 | 750 |

| AT 150-0.6 S G5plus | 600 | 7,800 | 120 | 73 | 1,000 | 1,300 | 1,900 | DN 250 | 870 |

| AT 150-0.8 G5plus | 800 | 5,400 | 120 | 73 | 1,000 | 1,300 | 1,900 | DN 250 | 870 |

| AT 150-1.0 S G5plus | 1,000 | 4,800 | 130 | 73 | 1,000 | 1,300 | 1,850 | DN 250 | 870 |

| AT 200-0.8 S G5plus | 800 | 8,400 | 165 | 73 | 1,000 | 1,300 | 1,850 | DN 250 | 870 |

| AT 200-1.0 S G5plus | 1,000 | 6,000 | 165 | 73 | 1,000 | 1,300 | 1,850 | DN 250 | 870 |

| AT 250-0.9 S G5plus | 900 | 9,400 | 190 | 76 | 1,000 | 1,300 | 1,850 | DN 250 | 870 |

Sound pressure level without blow-off noise, with acoustic enclosure.

* corresponds to the measured delivery volume flow converted to the customer-specific suction conditions p = 1,0 bar, t =20°C, rF = 0%