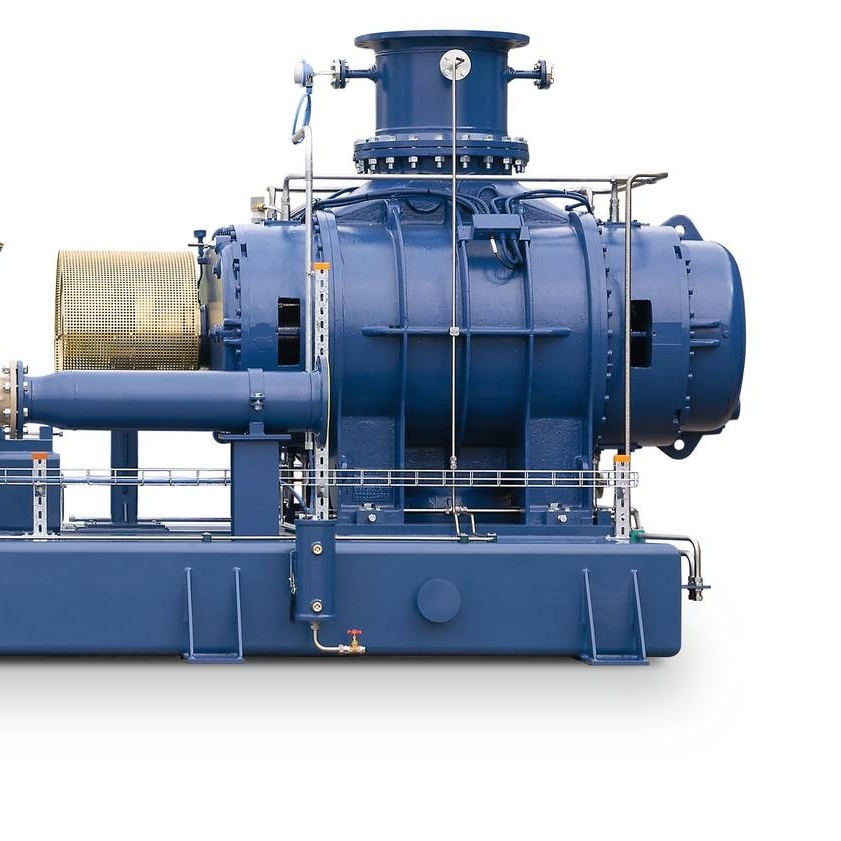

Positive Displacement Blowers

Process Gas Blower

Series GR

AERZEN offers the process gas and coolant industries an incredibly broad spectrum of blower technologies – perhaps the broadest of any manufacturer. Machines that operate as stand-alones, in machine or container combinations, onshore and offshore.

Volume flow:

52.974

to

21.189.6

CFM

Differential pressure (Δp):

2.18

to

21.76

psi

Medium:

Process Gases

Conveying:

Oil-free

The advantages of AERZEN Blower series GR at a glance:

- The 1 or 2 stage process blowers GR can be used for almost all technical gases and gas mixtures, which may also be aggressive.

- Versatile blower stage (single and two-stage) for plant engineering for vertical and oil-free conveyance.

- Direct drive, with gear box or belt drive. Optionally available with liquid injection for gas cooling or purification, as well as with special modifications and materials.

US Units

Yes- Type of technology

- Positive Displacement Blowers

- Differential pressure (Δp)

- 2.18 to 21.76 psi

- Volume flow

- 52.974 to 21.189.6 CFM

- Medium

- Process Gases

- Conveying

- Oil-free

Blower Power For Special Requirements

The 1- or 2-stage process blowers GR can be used variably for almost all technical gases and mixed gases. In all industrial sectors. Ideal also for gases with negative intake temperatures down to -40 °C. The process gas blower type GR can also be used to convey aggressive gases Maximum pressure increase of 1.5 bar, maximum pressure 6 bar g

Design

The conveying chamber is completely separated from the oil sumps by a space open to atmosphere.

- Maximum pressure increase of 1.5 bar

- Maximum pressure 6 bar (g)

Shaft Seals:

Conveying chamber sealed by

- a) pressure relieved soft packings with purge gas connections,

- b) pressure relieved carbon ring - labyrinth seals with purge gas connections,

- c) double-acting mechanical seals, oil-purged,

- d) double-acting mechanical seals, water-purged.

Drive shaft by radial seal ring.

Direction og flow:

Vertically downwards.

Drive:

Direct via flexible coupling or via flexibly coupled spur gear. Overhung via narrow V-belt (up to 250 kW driving power).

Special materials: Depending on the particular operating conditions, models are also available in nodular graphite cast iron or CrNi cast steel.