Vacuum Pumps

Technology & Application

Vacuum technology refers to any processes operating in gas conditions significantly lower than atmospheric pressure, namely below the threshold of -700 mbar (negative pressure) – equivalent to a value of 300 mbar absolute. At AERZEN, we have been providing custom vacuum technology and fabrication solutions to companies worldwide since the 1940s. We offer industrial vacuum systems such as vacuum pumps and motor blowers that are crucial to the creation, maintenance, and measurement of partial and full vacuum states. We are committed to giving our customers cost-effective vacuum technology via heavy-duty vacuum pumps that combine power, durability, and modularity for multiple applications.

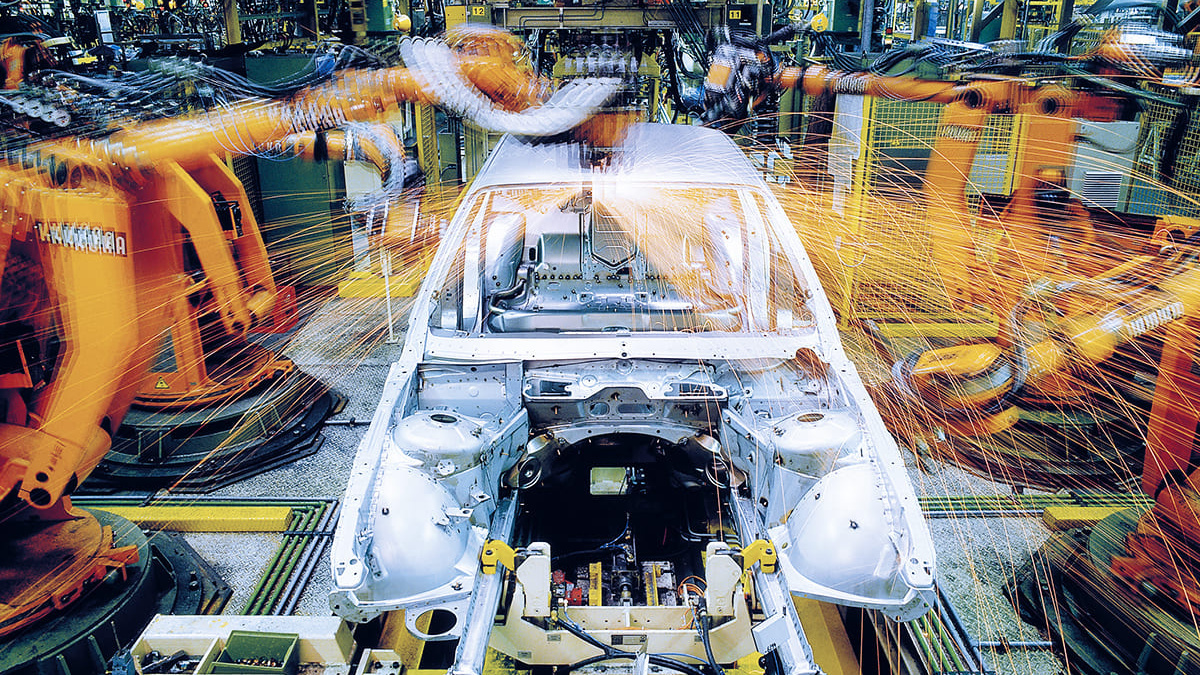

Types of vacuum technology and their industry applications

There are several types of vacuum pump and blower systems available, and choosing the right equipment is incredibly important to enable you to build, maintain, and improve your industrial vacuum systems. These types of technologies are industry-specific; for instance, vacuum pump blowers for the steel industry may not be suitable in the aeronautical space. A vacuum exists in five pressure ranges, measured in mbar or Torr (equivalent to millimeter of mercury or mmHg):

- Rough/Low: 1000 - 1 mbar/760 - 0.75 Torr

- Fine/Medium: 1 - 10-3 mbar/0.75 - 7.5-3 Torr

- High: 10-3 - 10-7 mbar/7.5-3 - 7.5-7 Torr

- Ultra-High Vacuum: 10-7 - 10-11 mbar/7.5-7 to 7.5-11 Torr

- Torr Extreme High Vacuum: < 10-11 mbar /< 7.5-11 Torr

Various kinds of systems used in industry operate within these five vacuum ranges. At AERZEN, we offer custom-made vacuum equipment designed to meet the rigors of a wide range of industrial processes for customers all over the world. Our vacuum pump components are designed to produce, maintain, and measure a full or partial vacuum state to ensure optimal operational efficiency.

Air pressure plays a central role in countless production processes, technology and several other industries. In the metal, chemical, and food industries, as well as in pharmaceuticals, the need for reliable control of the required pressure is high. Vacuum technology is becoming increasingly important, thus making numerous processes inconceivable or even result in unsatisfactory quality. A vacuum is when the atmospheric pressure falls below the threshold of -700 mbar – corresponding to a value of 300 mbar absolute. On the other hand, one talks about negative pressure when the value exceeds this.

Vacuum does not mean vacuum to everyone in the industry. The range below 300 mbar can be broken down even further, beginning with the fine and high vacuum and moving up to the optimal ultra-high vacuum. A perfect vacuum would be able to reach an absolute pressure of 0.0000 mbar. The added term “absolute” refers to the perfect vacuum and is used in vacuum technologies as the standard. Without so-called vacuum pump units, it would not be possible, to reach this range. AERZEN vacuum blowers have been considered to be one of the most reliable in the field since 1940.

When comparing vacuum pumps to compressors, the main difference is in the product results; generating vacuum pressure, or excess pressure, is physically achieved via similar methods. While a compressor compresses the outside air in a pressure tank, blower releases the gases outside, thus evacuating the gas from any sealed room. Using vacuum blowers is not only limited to air-related industrial tasks, but can also be used with all possible gases. It is also important to know that not every vacuum blower is suitable for numerous applications and processes. Depending on the different properties of gases, and the size of their molecules, the technology has to be synchronised with the desired task.

In addition, taking the environmental conditions into account is also an important factor in which a vacuum blower should be used. Especially in the chemical, pharmaceutical and food industries, difficult production requirements prevail. There are also gases that are aggressive to equipment or even cause health hazards in industrial use. Others are dangerous. For this reason, it is essential that the correct separation of evacuated gases, and their proper disposal, are never neglected.

Depending on the strength of the desired vacuum, AERZEN offers a variety of components that can reach and maintain the precise desired values. AERZEN has a wide range of equipment that offers the right solution for every demand.

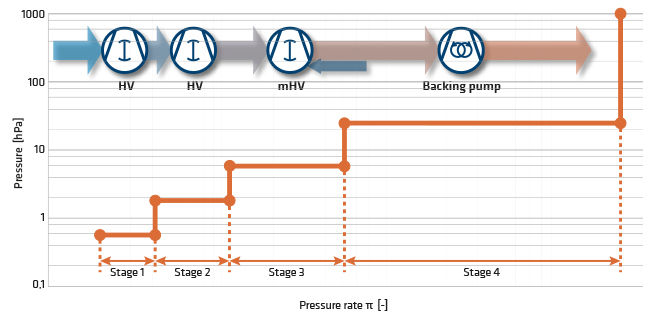

Adhering to desired parameters for specific needs in vacuum and high vacuum technology is extremely important. It is also important to recognise these circumstances beforehand, so the right equipment is used. For example, parameters needed in the steel industry vary immensely from the application of vacuum blowers elsewhere. Depending on the requirements needed, so-called pumping stations work using several levels and, in general, more than two levels are used. Without such pumping stations, an economical production of a low, fine and high vacuum would not make sense – let alone be possible. The interaction of pre-pumps and rotary blowers signals the use of two-level pumping stations. While the negative pressure can be reached between 500 mbar and 300 mbar absolute at one level, it is well under the threshold for vacuums and a combination of pre-pumps and vacuum rotary blowers is necessary. Here, the pre-pump already reduces the pressure in the first step in the respective tank or room. Next, the rotary blower can be turned on and can, combined with the pre-pump, produce the desired final vacuum or volume flow that is required for the particular application. In order to plan the vacuum unit correctly, the operator must specify the necessary parameters to the manufacturer. This includes the size of the factory floor to be evacuated, or rather the maximum required vacuum (or volume flow), as well as the maximal permitted time to expel the gases – for proper diffusion. When speaking about the maximal required vacuum, the point of operation is also important to mention. Depending on the demand, the appropriate pre-pump can be combined with exactly the right vacuum blower.

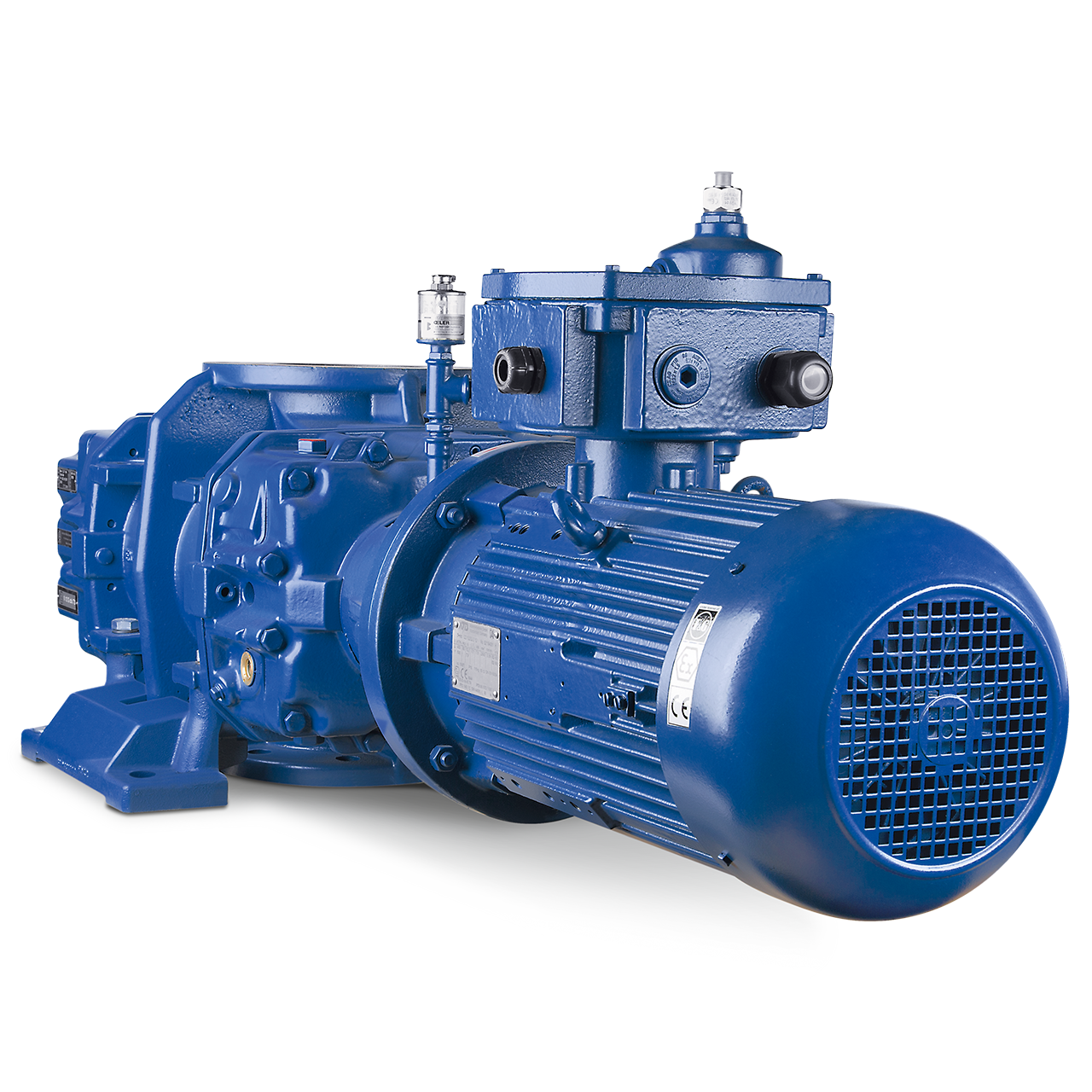

The majority of the pre-pump systems are selected specifically for the desired areas of application. Therefore, water ring pumps, greased rotary vane pumps or adjustable claw pumps are available. And, with them, neutral gases can be handled very well. The application of screw vacuum pumps make sense when the evacuation requirements are extremely high. Similar to screw compressors, a screw vacuum pump works very uniformly and precisely. The high energy efficiency, low-noise and low wear-and-tear in vacuum production via screw vacuum pumps is certainly expensive.

No matter which AERZEN solution you choose for your vacuum production needs, all components of pre-pumps and vacuum blowers are thermally and energetically coordinated perfectly together. Thus, a more reliable and durable pump system is guaranteed while focusing on energy efficiency. AERZEN canned motor blowers are recommended for the highest demands in industrial vacuum technology. They are the most suitable for long-term operation and feature a short expel time. Besides the compact cubic capacity, with which such blowers are ideal in combination with additional blowers, they are available in various constructions for different areas of application. AERZEN offers the CM for aggressive gases and HM for neutral gases.

AERZEN integrates and coordinates its products to meet the specific needs of its customers and by offering tailored solutions. With a variety of different possible uses, and the high demands, it is not possible to simply pull a complete solution off the shelf. It is a fact that the conception and planning of a pumping station is always individual case to case. This is the only way for individual components, available for the desired performance parameters for pre-pumps and vacuum rotary blowers, to be perfectly coordinated. The professional and competent consultations from AERZEN are an integral part of the entire offer. To ensure that the required parameters of the end product are adhered to, AERZEN conducts comprehensive software tests, thereby not only does the actual production of the vacuum stand out, but also the long-term durability, as well as the energetic values. Thus, critical thermal pressure ranges can be avoided that can lead to problems when continuously in operation.

Especially during long-term operation, it is not only important to adhere to the desired parameters for the produced vacuum, but also to take energy efficiency into account. Even for environmental protection reasons, vacuum pumps are equipped with highly-efficient technology. Energy consumption is especially important to industries with generally high energy costs. This applies to steel production plants – the energy guzzlers. Even more so, the definition of cost-cutting and high-performance components via the conception of pumping stations is extremely critical. All of AERZEN vacuum components are not only manufactured with the highest precision, they also fulfil the most important standards in the sense of energy optimisation when implementing systems. Complying with these values, trouble-free continuous operation is guaranteed without burdening the environment – or your budget.

![[Translate to English US:] Canned motor blowers [Translate to English US:] Canned motor blowers GM8000](/fileadmin/user_upload/01_images/01-05_subpages/01-05-01_products/positive_displacement_blowers/vacuum_pumps/canned_motor_blowers/GM_8000_1.png)

![[Translate to English US:] AERZEN Vacuum [Translate to English US:] Vacuum with pre-inlet cooling MHV](/fileadmin/user_upload/01_images/01-05_subpages/01-05-01_products/positive_displacement_blowers/vacuum_pumps/vacuum_with_pre-inlet_cooling/Blower-Vakuum-mit-Voreinlass-MHV.png)