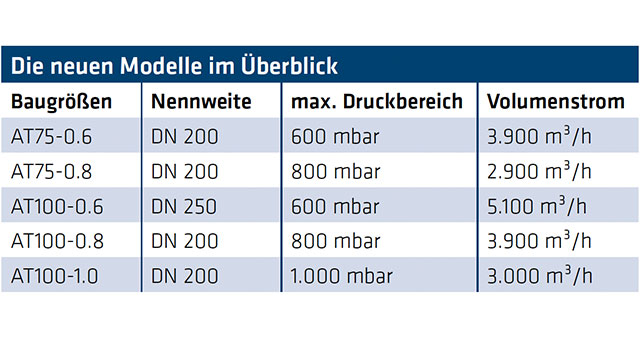

Mit der neuen Generation Aerzen Turbo G5plus hat AERZEN den kompaktesten und effizientesten Turbo seiner Klasse entwickelt. Mit den beiden neuen, ab sofort verfügbaren Modellen AT75 und AT100 ist das Aerzen Turbo G5plus Portfolio nun um weitere fünf auf 13 Baugrößen erweitert und komplettiert worden.

[Translate to German:] TURBO BLOWERS – FOR THE RELIABLE AND EFFICIENT AIR SUPPLY OF AERATION TANKS

[Translate to German:]

The air supply of modern wastewater treatment plants is clearly designed for maximum availability, high energy efficiency and long maintenance cycles. Therefore, AERZEN does not use oil or other lubricants for the demanding bearings within the turbo blowers of the current series Aerzen Turbo G5plus, AERZEN uses simply air. Thanks to the new turbo generation, AERZEN has created a more robust and more efficient solution compared to highly complex magnetic bearings.

As an effective bearing without any mechanical friction at all, AERZEN uses compressed air in the two radial drive shaft bearings and the axial bearing for absorbing the axial forces. In doing so, in no case, air is pumped with high pressure externally into the bearing shell, but rather in a brilliantly simple way, the compressor principle is used. Due to natural unbalance, when starting the turbo blower, the rapidly rotating shaft generates an eccentric circular motion in the air gap of the bearing. With the minimal distance to the bearing wall, the shaft increases the pressure in this area, and counterforce is generated in the form of an increase in pressure. This forces the shaft back in the opposite direction. Due to the rapidly increasing speed, the shaft centers in the bearing itself and increases the pressure in the air gap to more than 30 bar. The prevailing force couples are so high, that they keep the shaft permanently in the centre of the bearing, even in case of considerably varying and challenging operation conditions, and this takes place in free-floating manner without surface contact. The highlight of this AERZEN principle is that the air cushion forms itself during operation and - in contrast to magnetic bearing (see information box) - without further energy input. Initially, the air foil bearing was developed by NASA and has now been further optimised by AERZEN for turbo technology.

Concerning the air foil bearing principle no electrical, mechanical or pneumatic regulations are necessary - not even in case of dynamic load changes. It is true that wear friction can develop during start-up of the turbo blower until the air cushion is formed. In order to face this theoretical possibility, AERZEN has developed an innovative air foil bearing system. AERZEN uses a 2-component coating as the maintenance-free friction partner, which serves as a reliable lubricating film on contact with the shaft. As the compressor compresses the air in the bearing so densely, the layer between bearing ring and shaft is practically as hard as steel. Consequently, AERZEN has designed a damping layer specifically for this application - the spring foil. This is a millimetre thick plate which, when rolled into an undulating shape, supports the lubricating layer of the bearing and absorbs vibrations at the same time.

[Translate to German:] AIR FOIL BEARING VS. MAGNETIC BEARING

[Translate to German:]

Turbo blowers from other manufacturers work with magnetic bearings, which also aim to overcome the high speeds without any mechanical bearing. However, with the older technology of magnetic bearings electrical current is needed, so that the coils, arranged circularly around the drive shaft, can develop their forces during operation and have the shaft rotating free from mechanical friction. Particularly changing operation conditions put the highly complex regulation system of the magnetic bearings to a test. Frequently it comes to safety shutdowns of the entire turbo blower due to technological reasons. To ensure, that in case of a malfunction, an emergency shutdown, or a power failure, the system remains active for a certain period of time, turbo blowers with magnetic bearings must always be equipped with an uninterruptible power supply (UPS). Consequently, the UPS inevitably increases the life-cycle costs. A similar expenditure is necessary for the magnetic bearing system, as – permanently in operation – it uses electrical energy continuously. Its complex regulation technology necessitates regular maintenance intervals. The innovative air foil bearing from AERZEN has been designed for a theoretical bearing life of 80,000 operating hours independent of start/stop cycles, and sets a new standard in the market.

Artikel

- Artikel Aerzen Turbo G5plus, jetzt mit 13 Baugrößen

Neue Modelle AT75 und AT100 sind ab sofort verfügbar

AERZEN bietet die Baureihe Aerzen Turbo G5plus jetzt für Volumenströ-me von 300 m³/h bis 8.400 m³/h und für maximal 1.000 bar Druck lückenlos an. Die aktuelle Auswahl an Gebläsegrößen reicht vom kleinen AT 25-0.8 G5plus bis zum größten Modell AT 200-1.0 G5plus.

Die Baureihe Aerzen Turbo G5plus macht ihrem Namen alle Ehre, denn sie besticht durch zahlreiche Pluspunkte. So verfügen auch die fünf neuen Turbo-Modelle über ein extrem kompaktes Design und kommen mit geringstem Platzbedarf aus. Weitere herausragende Features sind die innovative AERZEN Luftlagerung mit Doppelbeschichtung und die neue Multilevel-Frequenzumrichtertechnologie, die die Wärmeverluste im Motor auf ein Minimum reduziert und damit den Gesamtwirkungsgrad entscheidend verbessert. Ein weiterer Pluspunkt: Auf eine zusätzliche Motordrossel oder einen Sinusfilter, die bei herkömmlichen Frequenzumrichtern eingesetzt werden müssen, kann hierbei verzichtet werden. Ebenfalls entscheidend weiterentwickelt ist die neue Luftspaltlagerung mit Doppelbeschichtung, bestehend aus Teflon und Grafit. Sie überzeugt durch eine erhöhte Temperaturbeständigkeit und eine erhöhte Lebensdauer von > 80.000 Betriebsstunden unabhängig von Start- und Stoppzyklen.

Alle Vorteile auf einen Blick:

- Erhöhung der Energieeffizienz um bis zu 10 % gegenüber konventioneller Turbotechnologie

- Verlängerte Lagerlebensdauer dank innovativer AERZEN Luftlagerung mit Doppelbeschichtung, höchste Zuverlässigkeit auch bei extremen Betriebsbedingungen

- 100 Prozent ölfrei

- Geringster Wartungsaufwand, nur regelmäßiger Filterwechsel

- Erweiterte Einsatzmöglichkeiten bei Umgebungstemperaturen bis 50 °C

- Aktiver Pumpschutz durch automatische Drehzahlerhöhung

- Platzsparendes Design